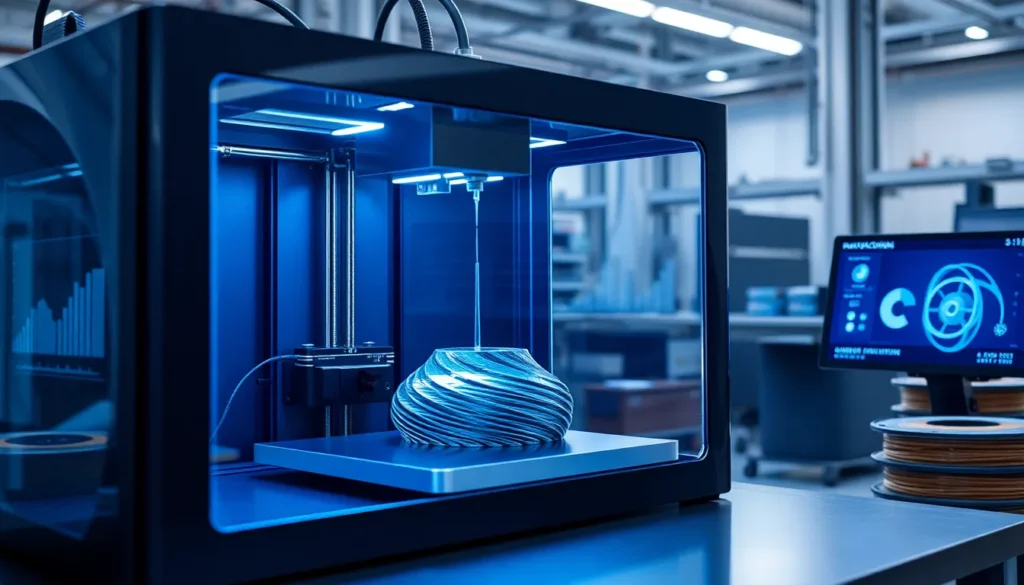

3D printing trends in 2026 are reshaping how industries manufacture, design, and innovate. From sustainable materials to AI-powered workflows, the technology is maturing fast. Businesses and hobbyists alike are paying close attention. This year brings significant shifts in speed, scale, and application. Whether someone works in aerospace, healthcare, or product design, understanding these 3D printing trends matters. Here’s what to expect as the industry moves forward.

Table of Contents

ToggleKey Takeaways

- 3D printing trends in 2026 prioritize sustainability, with recycled and biodegradable materials becoming cost-effective and widely available.

- AI-powered tools now optimize designs and monitor prints in real time, reducing material waste and failed prints significantly.

- Metal 3D printing has become affordable for smaller businesses, with desktop systems capable of producing steel, copper, and titanium parts.

- Healthcare applications are expanding rapidly, from patient-specific implants and surgical guides to early-stage bioprinting of living tissues.

- Faster print speeds and larger build volumes are making 3D printing viable for full-scale production and next-day custom part delivery.

- These 3D printing trends are transforming industries like aerospace, automotive, healthcare, and product design in measurable ways.

Advances in Sustainable and Recycled Materials

Sustainability has become a core focus for 3D printing in 2026. Manufacturers are producing filaments from recycled plastics, agricultural waste, and even ocean debris. These materials perform well and reduce environmental impact.

PLA and PETG remain popular, but newer options are gaining ground. Recycled nylon, for instance, offers strength comparable to virgin materials. Some companies now sell filaments made entirely from post-consumer waste. The cost difference has narrowed, making eco-friendly choices practical for more users.

3D printing trends also show growing demand for biodegradable options. Hemp-based and algae-derived filaments are entering the market. These break down naturally, unlike traditional plastics that linger in landfills for centuries.

Corporate buyers are driving much of this shift. Large companies want greener supply chains. They’re specifying recycled materials in contracts and tracking carbon footprints more closely. This pressure pushes material suppliers to innovate faster.

For hobbyists, the news is equally good. Recycled filaments cost less than they did two years ago. Quality has improved significantly. Print failures due to material inconsistency have dropped as manufacturing processes mature.

AI-Driven Design and Print Optimization

Artificial intelligence is changing how people design for 3D printing. In 2026, AI tools can generate optimized geometries in minutes. These designs use less material while maintaining structural integrity.

Generative design software has become more accessible. Users input constraints like weight limits, stress requirements, and material type. The AI produces multiple design options that meet these parameters. Engineers then select the best fit for their needs.

3D printing trends show AI also improving the printing process itself. Machine learning algorithms predict print failures before they happen. Sensors monitor temperature, layer adhesion, and material flow in real time. When something drifts from optimal settings, the software adjusts automatically.

This reduces waste significantly. Failed prints have always been a frustration and expense. AI-powered monitoring catches problems early, often saving hours of print time and material.

Slicing software has grown smarter too. AI-enhanced slicers analyze models and suggest optimal orientations, support structures, and infill patterns. The learning curve for beginners has shortened because the software handles more decisions automatically.

Some platforms now offer cloud-based AI services. Users upload their designs and receive optimized files back. This democratizes access to advanced tools that previously required expensive software licenses.

Expansion of Metal 3D Printing Applications

Metal 3D printing is moving beyond prototyping into full production. In 2026, more manufacturers are using it for end-use parts. The economics finally make sense for many applications.

Aerospace companies have led adoption for years. They print lightweight brackets, fuel nozzles, and structural components. Now automotive and energy sectors are catching up. Turbine blades, custom tooling, and heat exchangers are common metal 3D printing applications.

3D printing trends indicate that costs are dropping. Newer machines require less powder per part. Recycling systems recover unused material efficiently. Competition among equipment makers has pushed prices down across the board.

Bound metal deposition and binder jetting have matured considerably. These methods skip expensive lasers. They work more like traditional FDM printing but with metal-filled materials. After printing, parts go through sintering to achieve full density.

Smaller businesses can now afford metal 3D printing. Desktop systems capable of producing steel, copper, and titanium parts exist at price points that seemed impossible five years ago.

Quality control has improved alongside the technology. Automated inspection systems verify dimensional accuracy and detect internal defects. This gives manufacturers confidence to use printed metal parts in critical applications.

Growth in Medical and Bioprinting Innovations

Healthcare is one of the most exciting areas for 3D printing trends in 2026. Custom implants, surgical guides, and prosthetics are now routine applications. Hospitals increasingly have their own printing labs.

Patient-specific implants fit better than off-the-shelf alternatives. Surgeons use CT and MRI data to create perfect matches for bone replacements. Recovery times often improve because the body accepts these custom devices more readily.

Bioprinting is advancing steadily. Researchers are printing living tissues for drug testing and research. Skin grafts created through 3D printing are entering clinical trials. Cartilage and bone scaffolds show promising results in early studies.

Full organ printing remains years away. But progress continues. Scientists have printed small-scale kidney and liver structures that function briefly in lab settings. Each year brings incremental improvements.

Dental applications have expanded rapidly. Same-day crowns, aligners, and dentures are common. 3D printing has cut costs and wait times dramatically compared to traditional methods.

3D printing trends also show growth in personalized medication. Some pharmacies now print pills with customized dosages. This helps patients who need precise amounts that standard pills don’t offer.

Faster Speeds and Larger Build Volumes

Speed and size limitations have always constrained 3D printing. In 2026, both barriers are falling. New machines print faster and bigger than ever before.

High-speed resin printers now produce parts in minutes rather than hours. Continuous liquid interface production and similar technologies have matured. These systems maintain quality while dramatically reducing cycle times.

FDM printers have accelerated too. Input shapers and advanced motion control allow print heads to move faster without sacrificing accuracy. Consumer machines routinely hit speeds that would have destroyed earlier models.

3D printing trends show build volumes increasing across all price points. Industrial machines can produce car-sized parts in single pieces. Even desktop printers offer larger beds than their predecessors.

This matters for practical applications. Larger build volumes mean fewer assemblies. Parts that once required joining multiple pieces now print as unified structures. This improves strength and reduces post-processing work.

Pellet-fed systems are gaining popularity for large-scale work. They use plastic pellets instead of filament, cutting material costs significantly. These machines suit furniture, architectural elements, and industrial fixtures.

Faster printing also changes business models. Shorter lead times make 3D printing viable for more orders. Companies can offer next-day delivery on custom parts that previously took weeks.