In a world where imagination runs wild and creativity knows no bounds, 3D printing technology stands out as the superhero of innovation. It’s like having a magic wand that transforms digital designs into tangible objects faster than you can say “abracadabra.” From crafting intricate prototypes to creating customized toys, the possibilities are practically endless.

Table of Contents

ToggleOverview of 3D Printing Technology

3D printing technology transforms digital models into tangible items through additive manufacturing processes. This method builds objects layer by layer, allowing precise creation of complex shapes and intricate designs. Various materials, including plastics, metals, and ceramics, support 3D printing, catering to diverse applications across different fields.

Innovators in manufacturing leverage 3D printing for rapid prototyping. It accelerates product development cycles, enabling teams to visualize concepts quickly and test functionality. Significant time and cost savings characterize this approach, as traditional methods often require extensive setup and material waste.

Medical applications highlight the technology’s potential, particularly in producing custom prosthetics and implants. Personalized solutions replace generic alternatives, improving patient outcomes significantly. Additionally, research labs utilize 3D printing to create models for surgical training, enhancing the learning experience for medical professionals.

Aerospace and automotive industries benefit from lightweight components produced via 3D printing. Custom designs optimize performance while reducing material usage. Engineers rely on advanced software to simulate designs before production, ensuring functionality aligns with specifications.

Sustainability concerns drive advancements in 3D printing as well. The technology enables on-demand manufacturing, which reduces excess inventory and waste. Recycling materials for 3D printing also contributes to a circular economy, minimizing environmental impact.

Overall, 3D printing technology continues to evolve, presenting opportunities for innovation in countless sectors. Its ongoing development promises to reshape traditional manufacturing paradigms as industries embrace its capabilities.

Types of 3D Printing Technologies

3D printing technology encompasses various methods. Each technique serves unique purposes and applications, offering distinct advantages.

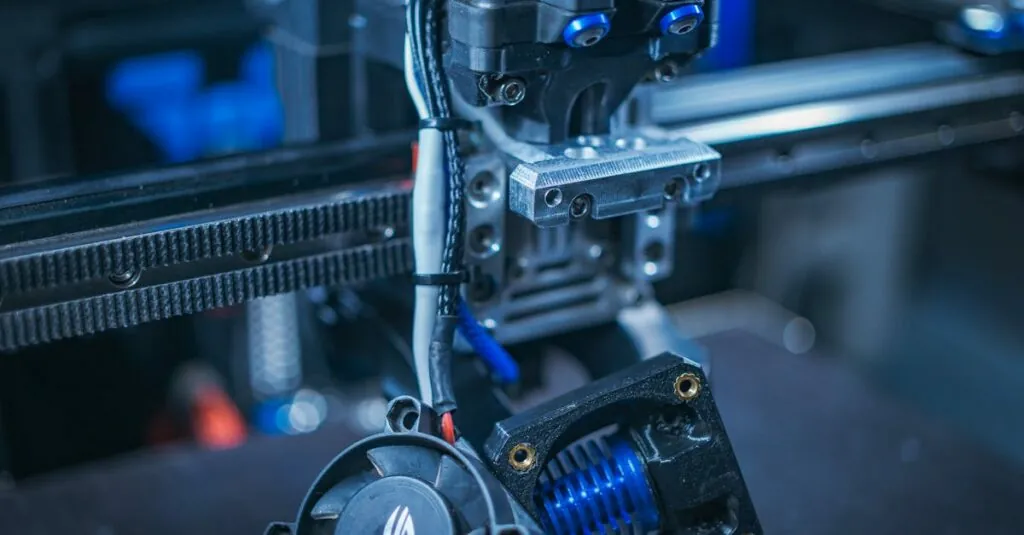

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) stands as one of the most commonly used 3D printing techniques. It works by extruding heated thermoplastic filaments layer by layer to construct an object. Users appreciate FDM machines for their affordability and ease of use, making them ideal for beginners. Materials like PLA and ABS are frequently used due to their versatility and availability. The resulting prints exhibit good strength and detail, suitable for prototyping and functional parts.

Stereolithography (SLA)

Stereolithography (SLA) utilizes a different approach by employing a liquid resin that cures when exposed to ultraviolet light. This technology allows for exceptional detail and surface finish, making it popular in industries requiring high precision, such as jewelry and dental applications. SLA prints tend to deliver smooth, intricate designs that traditional methods might struggle to achieve. However, they typically require post-processing steps to enhance durability and remove excess resin.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) adopts a laser to fuse powdered materials, often plastics like nylon or metals. The process involves layer-by-layer sintering, creating durable, robust parts. SLS excels in producing complex geometries that are difficult to achieve with FDM or SLA technologies. Its capabilities extend to functional prototypes and end-use parts, making it a preferred choice for aerospace and automotive industries. The lack of support structures required during printing further adds to its efficiency.

Applications of 3D Printing Technology

3D printing technology finds extensive applications across various industries, revolutionizing traditional practices and enhancing innovation.

Healthcare

In healthcare, 3D printing creates custom prosthetics and implants tailored to individual patients. It allows for the production of complex anatomical models that surgeons can use for planning procedures. Additionally, this technology aids in developing patient-specific surgical tools and devices, greatly improving treatment outcomes. Hospitals utilize 3D-printed models to simulate surgeries, enhancing training for medical professionals. Rapid prototyping in this field significantly reduces lead time, allowing for timely interventions.

Automotive Industry

The automotive industry benefits significantly from 3D printing’s capabilities. Manufacturers produce lightweight components that contribute to fuel efficiency and overall vehicle performance. Custom parts are easily fabricated, allowing for more innovative designs and faster iterations. Rapid prototyping speeds up the development cycle, enabling faster market entry for new models. Additionally, 3D printing offers the potential for on-demand production, reducing the need for large inventories and waste.

Aerospace Sector

Aerospace sector applications include the production of lightweight, durable parts essential for aircraft performance. 3D printing facilitates the manufacturing of complex geometries that traditional methods cannot achieve. Engineers utilize this technology to create prototypes quickly, expediting the testing process and reducing costs. Replacement parts can be printed on demand, minimizing downtime in operations. Furthermore, using advanced materials enhances the efficiency and reliability of aerospace components.

Advantages of 3D Printing Technology

3D printing technology offers various advantages that continue to impact multiple industries. Its unique features enable innovations in cost efficiency, customization, and sustainability.

Cost Efficiency

Cost efficiency stands out as a primary benefit of 3D printing technology. Traditional manufacturing methods often require significant investments in tooling and setup, while 3D printing minimizes these expenses. Lower material waste occurs because the additive process builds objects layer by layer, utilizing only the necessary amount of material. Speed also plays a crucial role, as rapid prototyping allows for quicker product iterations, reducing time-to-market. Companies save money due to streamlined processes that enable on-demand production, eliminating the need for large inventories.

Customization

Customization represents another significant advantage offered by 3D printing. This technology allows manufacturers to produce tailored products that meet specific customer needs. Patients benefit from personalized medical devices, such as custom prosthetics and implants, enhancing their healthcare experiences. Also, businesses can create unique prototypes that reflect client preferences, leading to improved satisfaction. Designers use 3D printing to experiment with intricate shapes and complex structures, pushing creative boundaries while satisfying diverse market demands.

Sustainability

Sustainability is increasingly important in today’s manufacturing landscape, and 3D printing contributes positively. On-demand production significantly reduces excess inventory and minimizes waste since items are manufactured only as needed. Materials can be recycled, promoting a circular economy that lowers environmental impacts. Additionally, efficient use of resources further enhances the eco-friendliness of this technology. By embracing 3D printing, industries can advance their sustainability goals while maintaining operational efficiency and cost-effectiveness.

Challenges and Limitations

3D printing technology faces several challenges and limitations that may hinder its widespread adoption. These obstacles include material constraints and regulatory issues, which can affect the overall effectiveness of the technology.

Material Constraints

Materials used in 3D printing hold specific characteristics that impact the quality and durability of printed objects. Limited material options can restrict applications, particularly in industries demanding high-performance parts. Traditional materials, like plastics and metals, might not meet the requirements for certain specialized functions. Compatibility of materials with different 3D printing methods poses another challenge, as each technique has unique material specifications. Moreover, certain materials can be costly or difficult to source, impacting the economy of production and making it difficult for businesses to scale effectively.

Regulatory Issues

Navigating regulatory landscapes presents significant challenges for 3D printing technology. In many sectors, including healthcare and aerospace, stringent regulations govern the safety and efficacy of products. Compliance with these regulations often requires extensive documentation and testing, which can delay product development. Intellectual property concerns arise as well, particularly regarding designs and patents associated with custom 3D-printed items. Additionally, the rapid pace of innovation leads to evolving regulations that can be challenging for manufacturers to keep up with, creating uncertainty in the market.

Conclusion

3D printing technology stands at the forefront of innovation across various industries. Its ability to create customized solutions quickly and efficiently is reshaping manufacturing processes and enhancing product development. As it continues to evolve the potential for new applications and improvements remains vast.

While challenges such as material limitations and regulatory hurdles exist the benefits of cost efficiency and sustainability can’t be overlooked. Embracing this technology not only leads to better products but also supports environmental goals through reduced waste. The future of 3D printing promises to unlock even greater possibilities for creativity and efficiency in a rapidly changing world.